Conveyor Solutions

Conveyors move materials, products, and loads throughout a manufacturing or distribution facility to achieve a more efficient, reliable and continuous facility operation. Loads ride atop rollers or a belt with a fixed path for loading and unloading.

Conveyors reduce costs and increase worker productivity by moving large volumes of material rapidly to pick, pack, and ship locations. There are two main categories of conveyors: gravity and power, each with several varieties of functionality, depending on the goals of each facility.

S&H Systems has the expertise and the product relationships that deliver the solutions you need. We work with large and small companies, developing systems that meet hundreds of criteria.

GOODS-TO-PERSON

Agile and effective automated order preparation & picking.

Efficient | Scalable | Responsive

S&H Systems’ Goods-to-Person and software-directed workstation technologies drive increased speed, efficiency, and accuracy in order fulfillment workflow. We have product applications for ecommerce, parcel sortation, and the warehouse and manufacturing industries. They are often selected for their dynamic functionality, efficient use of space, and improved work environments.

- Increase order efficiencies and operational uptime

- Eliminate order errors

- Ergonomic operator picking workstations

- Optimize space utilization for a small footprint and flexible layout

- High-density, consolidated storage

- Monitor orders, robots and inventory in real-time

- Warehouse software integration

Easily increase capacity by adding robots, modules, or workstations with little to no downtime

Automated storage / Retrieval Systems

Applications for cartons, totes, and pallets are integrated to create a goods-to-person powerhouse that delivers 99% accuracy. These systems have the flexibility to accommodate order bursts and the scalability that ecommerce companies need today.

AUTONOMOUS MOBILE ROBOTICS (AMR)

Our collaborative AMRs help your human assets work smarter. Flexible, intelligent, mobile robot units seamlessly align with your warehouse or manufacturing operations. They work together with humans, navigate autonomously, and work in coordinated swarms to drive productivity.

ROBOTIC PUT WALL

Robotics reduce costs and save valuable production time. Human-like hand-eye coordination measures, sorts, and picks/puts any number of conveyors, cells, products, and package configurations.

PICK/PUT WALL

Either traditional or robotic put walls, they can be integrated into manual and automated picking workflows to enhance efficiency while consolidating diverse products across multiple channels.

DIRECTED PICK/Put

This technology handles an unlimited number of SKUs in fast-moving and split-case picking operations. It reduces errors by up to 75% and can be configured for seasonal spikes or shifts in demand.

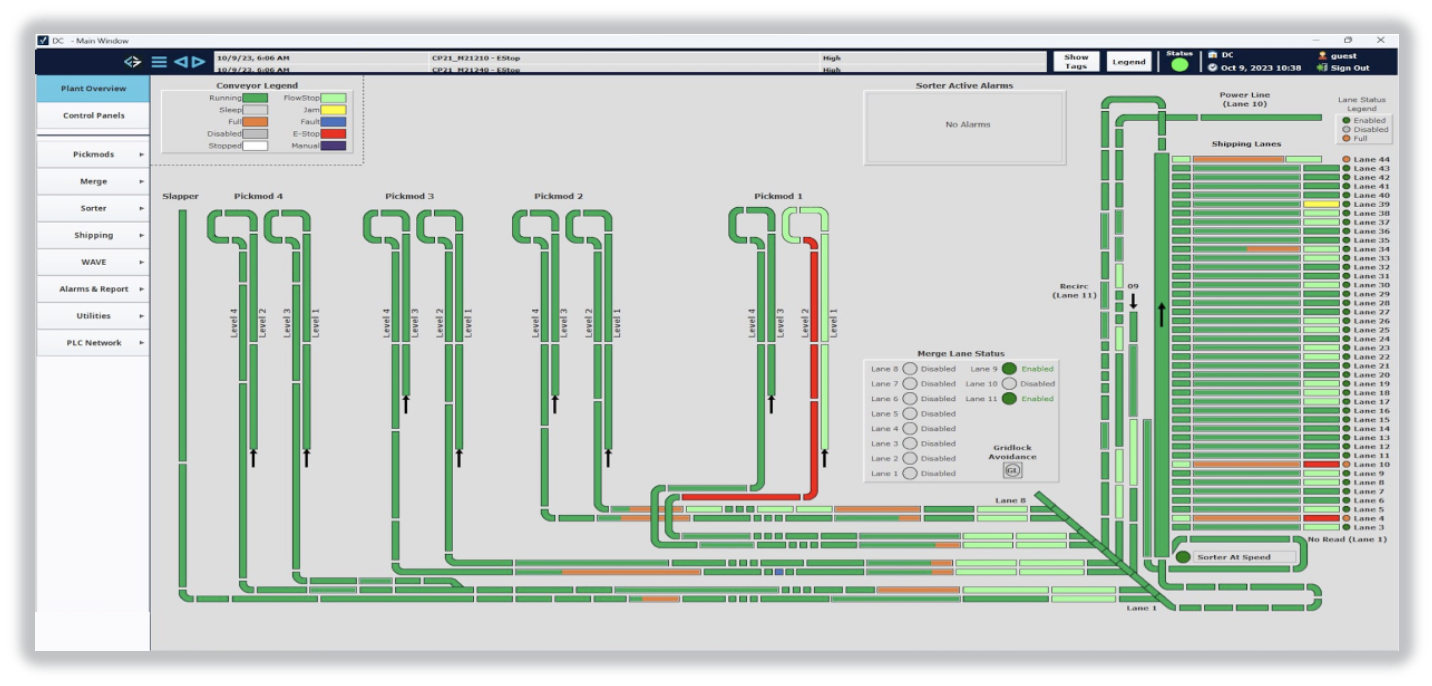

WCS / Controls

A Warehouse Control System (WCS) is the software for controlling material handling equipment. The WCS coordinates material handling systems at the controls level to determine the most efficient product flow and routing.

Real-time integration with the various material handling technologies is a driver of the efficiency of these systems. The ability of a WCS to seamlessly integrate into the automated material handling equipment.